玻璃鋼電纜橋架的結(jié)構(gòu)設(shè)計(jì)也對(duì)其低導(dǎo)熱系數(shù)起到了關(guān)鍵作用

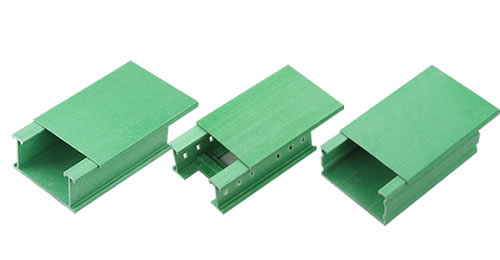

玻璃鋼電纜橋架,作為一種廣泛應(yīng)用于電力、通信、石化等行業(yè)的電纜支撐結(jié)構(gòu),其設(shè)計(jì)不僅關(guān)乎電纜的與穩(wěn)定,更在保障電纜正常運(yùn)行的同時(shí),對(duì)環(huán)境的熱管理起到了關(guān)重要的作用。其中,其特殊的結(jié)構(gòu)設(shè)計(jì)對(duì)于實(shí)現(xiàn)低導(dǎo)熱系數(shù)起到了關(guān)鍵作用,進(jìn)而保證了電纜橋架在各種環(huán)境條件下的運(yùn)行。

Fiberglass cable tray, as a widely used cable support structure in industries such as power, communication, and petrochemicals, its design not only concerns the safety and stability of cables, but also plays a crucial role in ensuring the normal operation of cables and thermal management of the environment. Among them, its special structural design plays a key role in achieving low thermal conductivity, thereby ensuring the efficient operation of cable trays under various environmental conditions.

,我們需要了解玻璃鋼電纜橋架的基本結(jié)構(gòu)和材料特性。玻璃鋼,作為一種復(fù)合材料,由玻璃纖維和樹脂基體復(fù)合而成,具有輕質(zhì)高強(qiáng)、耐腐蝕、絕緣性好等優(yōu)點(diǎn)。這些特性使得玻璃鋼電纜橋架在電纜敷設(shè)中能夠承擔(dān)重壓、抵御腐蝕,并有效防止電磁干擾。而橋架的結(jié)構(gòu)設(shè)計(jì),則決定了其在使用過程中對(duì)熱量的傳導(dǎo)和分散能力。

Firstly, we need to understand the basic structure and material characteristics of fiberglass cable trays. Fiberglass reinforced plastic, as a composite material, is composed of glass fibers and resin matrix, and has the advantages of lightweight, high strength, corrosion resistance, and good insulation. These characteristics enable fiberglass cable trays to withstand heavy pressure, resist corrosion, and effectively prevent electromagnetic interference during cable laying. The structural design of the bridge determines its ability to conduct and disperse heat during use.

在玻璃鋼電纜橋架的結(jié)構(gòu)設(shè)計(jì)中,低導(dǎo)熱系數(shù)的實(shí)現(xiàn)主要依賴于以下幾個(gè)方面:

In the structural design of fiberglass cable trays, the achievement of low thermal conductivity mainly depends on the following aspects:

一、合理的截面形狀設(shè)計(jì)

1、 Reasonable cross-sectional shape design

玻璃鋼電纜橋架的截面形狀設(shè)計(jì)直接關(guān)系到其熱傳導(dǎo)性能。通過優(yōu)化截面形狀,可以有效減少熱傳導(dǎo)路徑,降低橋架本身的熱傳導(dǎo)效率。例如,采用圓形或橢圓形截面設(shè)計(jì),相較于傳統(tǒng)的矩形截面,可以更有效地減少熱量在橋架內(nèi)部的傳遞,從而降低電纜的溫度,保障電纜的正常運(yùn)行。

The cross-sectional shape design of fiberglass cable trays directly affects their thermal conductivity performance. By optimizing the cross-sectional shape, it is possible to effectively reduce the heat conduction path and lower the heat conduction efficiency of the bridge itself. For example, using a circular or elliptical cross-section design can more effectively reduce the heat transfer inside the cable tray compared to traditional rectangular cross-sections, thereby lowering the temperature of the cable and ensuring its normal operation.

二、優(yōu)化的散熱結(jié)構(gòu)設(shè)計(jì)

2、 Optimized heat dissipation structure design

在玻璃鋼電纜橋架的設(shè)計(jì)中,散熱結(jié)構(gòu)的設(shè)計(jì)是降低導(dǎo)熱系數(shù)的關(guān)鍵。通過增加散熱片、散熱槽等結(jié)構(gòu),可以有效增加橋架表面的散熱面積,提高散熱效率。同時(shí),采用合理的散熱布局,可以使橋架在承受電纜重壓的同時(shí),保持良好的散熱性能,從而確保電纜在長時(shí)間運(yùn)行過程中的穩(wěn)定性。

In the design of fiberglass cable trays, the design of heat dissipation structures is the key to reducing thermal conductivity. By adding structures such as heat sinks and heat sinks, the heat dissipation area on the surface of the bridge can be effectively increased, improving heat dissipation efficiency. At the same time, adopting a reasonable heat dissipation layout can enable the cable tray to maintain good heat dissipation performance while bearing heavy cable pressure, thereby ensuring the stability of the cable during long-term operation.

三、良好的隔熱設(shè)計(jì)

3、 Good insulation design

為了降低玻璃鋼電纜橋架對(duì)周圍環(huán)境的熱傳導(dǎo),隔熱設(shè)計(jì)是不可或缺的。在橋架的外表面,可以采用添加隔熱材料、噴涂隔熱涂層等方式,降低橋架表面的熱輻射和傳導(dǎo)能力。此外,在橋架的內(nèi)部,也可以采用隔熱隔板、隔熱墊等結(jié)構(gòu),進(jìn)一步降低橋架內(nèi)部的熱量傳遞,保障電纜在較低的溫度下運(yùn)行。

In order to reduce the thermal conductivity of fiberglass cable trays to the surrounding environment, insulation design is indispensable. On the outer surface of the bridge, methods such as adding insulation materials and spraying insulation coatings can be used to reduce the thermal radiation and conductivity of the bridge surface. In addition, insulation partitions, insulation pads, and other structures can also be used inside the cable tray to further reduce heat transfer and ensure that the cables operate at lower temperatures.

四、智能溫控設(shè)計(jì)

4、 Intelligent temperature control design

隨著科技的不斷發(fā)展,智能溫控技術(shù)也逐漸被應(yīng)用到玻璃鋼電纜橋架的設(shè)計(jì)中。通過在橋架上安裝溫度傳感器、熱敏電阻等元件,可以實(shí)時(shí)監(jiān)測橋架內(nèi)部的溫度變化,并根據(jù)需要自動(dòng)調(diào)節(jié)散熱設(shè)備的運(yùn)行狀態(tài)。這種智能溫控設(shè)計(jì),可以更加精確地控制橋架的溫度,進(jìn)一步提高電纜的運(yùn)行效率和性。

With the continuous development of technology, intelligent temperature control technology is gradually being applied to the design of fiberglass cable trays. By installing temperature sensors, thermistors, and other components on the bridge, the temperature changes inside the bridge can be monitored in real time, and the operating status of the cooling equipment can be automatically adjusted as needed. This intelligent temperature control design can more accurately control the temperature of the cable tray, further improving the efficiency and safety of cable operation.

本文由濟(jì)南電纜橋架提供技術(shù)支持,更多精彩內(nèi)容請(qǐng)繼續(xù)關(guān)注我們的http://m.zkhtkj.cn,我們后續(xù)會(huì)有更多精彩內(nèi)容給您展現(xiàn).

This article is supported by Jinan cable tray technology. For more exciting content, please continue to follow us http://m.zkhtkj.cn We will have more exciting content to showcase to you in the future

下一篇:玻璃鋼電纜橋架表面維護(hù)注意事項(xiàng)

相關(guān)文章 / Recommended news

濟(jì)南電纜橋架到底需不需要跨接

濟(jì)南電纜橋架到底需不需要跨接 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架